MeHow has built extensive expertise in precision manufacturing for medical devices, accumulating a wealth of technology and experience. The company is fully capable of addressing the diverse manufacturing needs of clients, from the development of medical device components to the assembly of finished medical devices.

Precision Manufacturing Capability

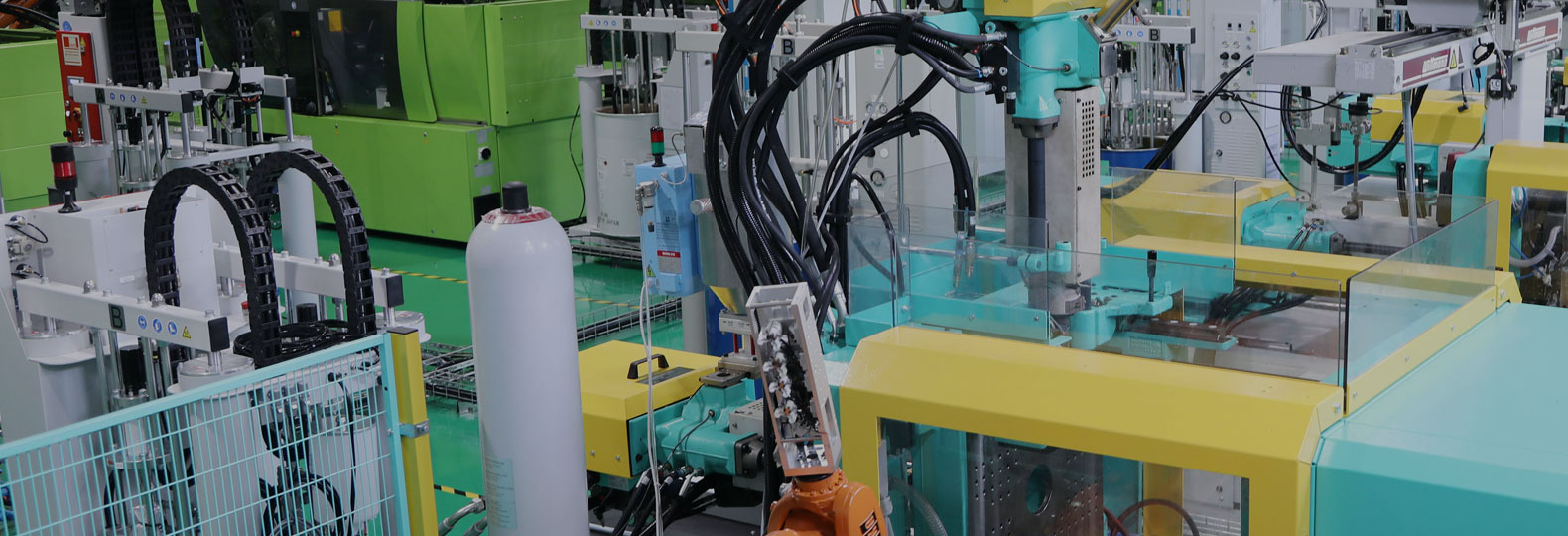

- Precision Plastic Injection Molding

- Precision LSR (Liquid Silicone Rubber) Injection Molding

- Medical-grade Extrusion (Flat Tubing, Threaded Tubing, Dual-material Threaded Tubing, Multi-layer Threaded Tubing)

- Product Post-processing (Ultrasonic Welding, Hot Melting, Pad Printing, Silk Printing, Hot Stamping, Laser Cutting, Laser Engraving)

- Medical-grade Precision Metal Components Processing (Ti, Niti, SS)

- Manufacturing of Finished Medical Passive and Active Devices

Integrated Precision Manufacturing Technology Services

- Manufacturing Process Design, Development and Validation

- Manufacturing Equipment Selection and Validation

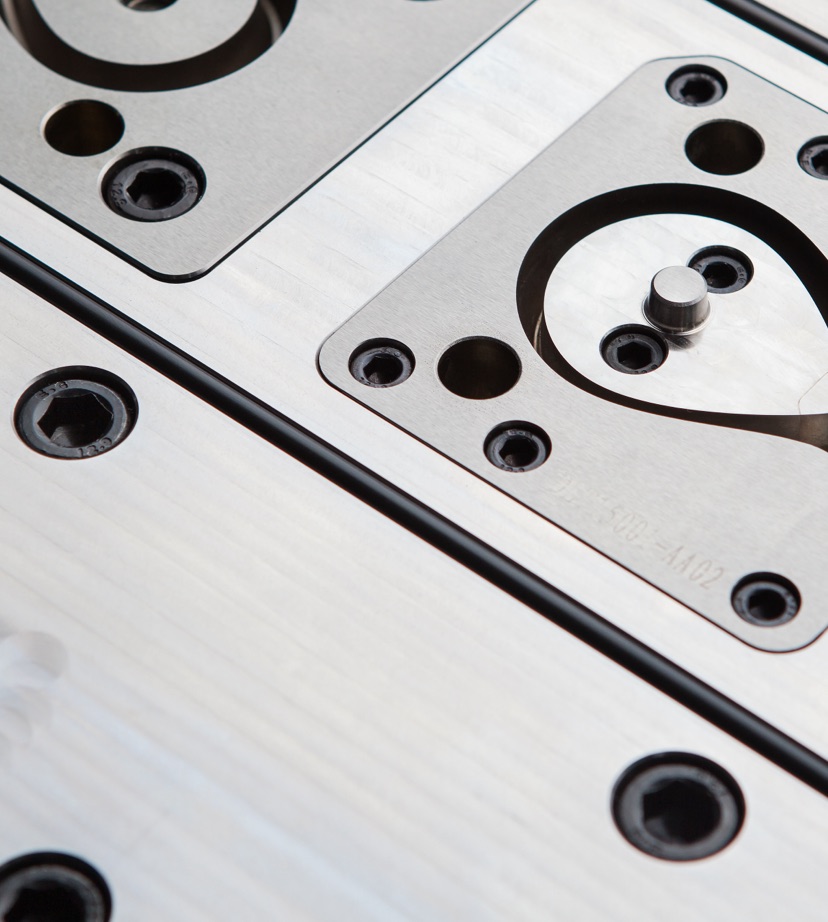

- High-speed Mold Design and Development

-

Molds, Fixtures and Jigs Design and Development

- Test Fixtures and Jigs Design and Development

- Prototype Development and Sample Production

-

Reliability Test

- Mass Production and Quality Inspection

- Comprehensive Turnkey Engineering Services

Solutions

Solutions