MeHow has a fully integrated sterile medical device manufacturing system, with extensive experience in producing Class II medical devices and Class III implantable medical devices. The company is equipped to meet the diverse GMP manufacturing requirements of its clients.

GMP Site Management System

The key factor in the safety of sterile and implantable medical devices is effective contamination control, addressing particles, microorganisms, and chemical contaminants. A robust manufacturing system forms the foundation for preventing contamination, ensuring the safety and effectiveness of the devices.

- GMP Workshop Hygiene Management System

- Cleaning and Disinfection Management System

- Identification and Traceability Management System

- Site-clearing Management System

- Batch Record Management System

- Product Release Management System

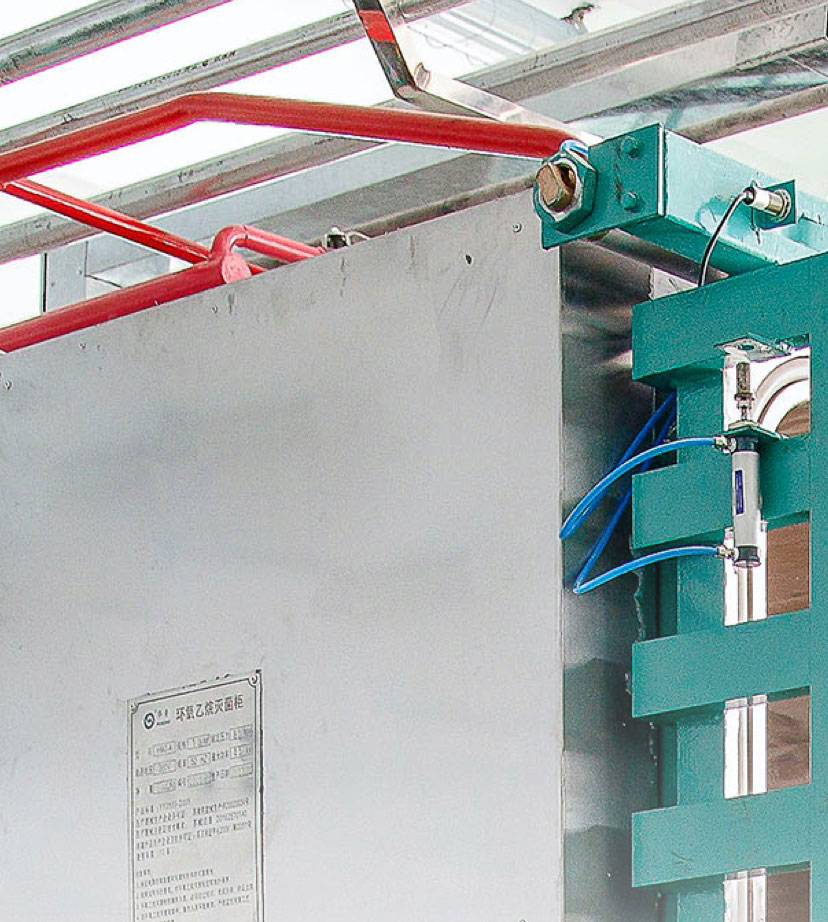

GMP Facility

Infrastructure is essential to ensuring the quality of medical device manufacturing. The company has established a fully equipped GMP facility that meets the manufacturing standards for Class II and Class III implantable medical devices.

- Class 7 & Class 8

- Purified Water Production

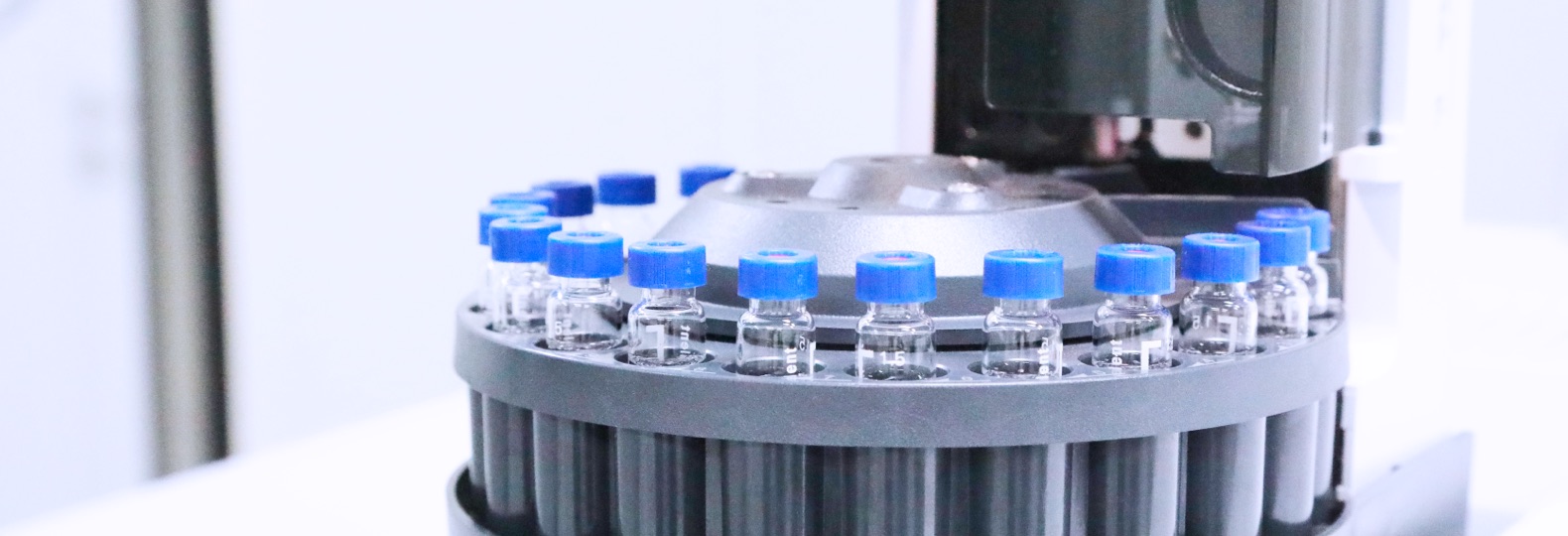

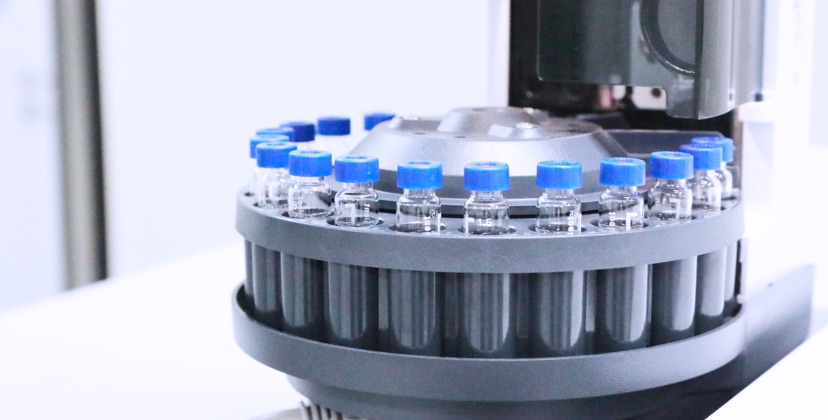

Testing Center

The cleanroom must consistently test and monitor the environment to ensure it meets production standards. Before medical devices are approved for manufacturing, they undergo testing to ensure compliance with technical specifications and legal requirements.

- Environmental Monitoring Capability (Particle, Temperature and Humidity, Number of Ventilation, Pressure Difference, Sedimentation Bacteria or Planktonic Bacteria)

- Mechanical Performance Test (Size, Welding Strength, Flow Rate, Leakage, Heat Sealing Strength)

- Microbiological Performance Test (Initial Contamination Test, Sterilization Test)

- Reliability Test (Validity Test, Simulated Transportation Test)

Solutions

Solutions